Discover Aluminum Foundry and its leading role in today’s aluminum casting

Wiki Article

Comprehending the Various Sorts Of Procedures in An Aluminum Foundry for Effective Manufacturing

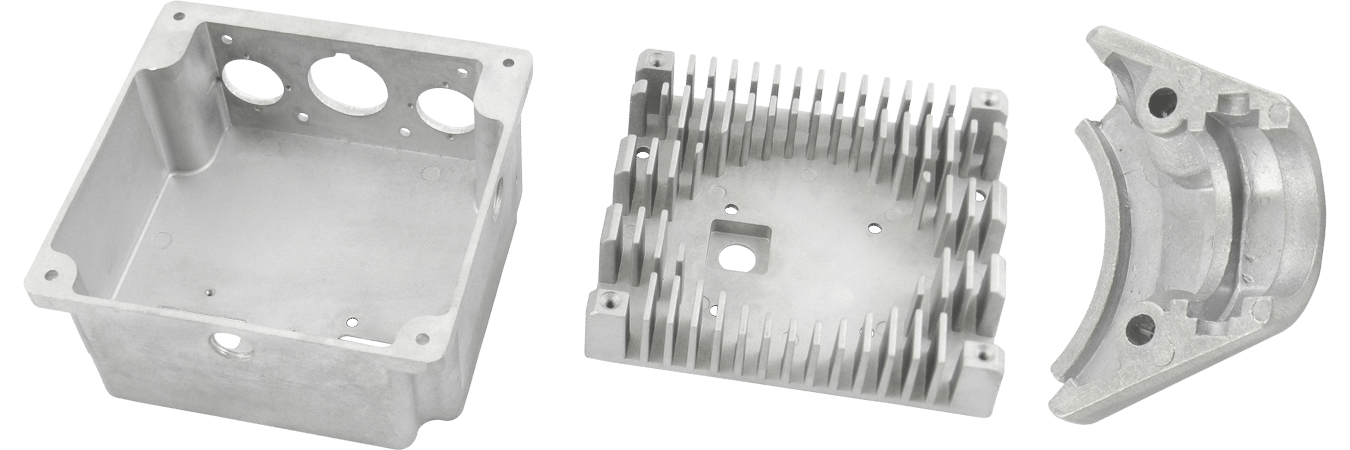

In An Aluminum Foundry, different casting procedures play an important duty in manufacturing effectiveness. Each approach, from sand spreading to die casting, supplies distinct benefits that deal with details producing requirements. Recognizing these processes is essential for enhancing top quality and price. The option of casting technique can considerably influence total result. As factories check out these options, they should consider which techniques straighten ideal with their production goals. What aspects will ultimately guide their decisions?Summary of Aluminum Foundry Processes

Aluminum Foundry processes include a series of specialized methods targeted at transforming raw Aluminum right into usable components. These procedures commonly begin with thawing the Aluminum, where primary or scrap Aluminum is heated up till it gets to a molten state. As soon as thawed, the Aluminum might undertake alloying, where particular components are included to boost its residential or commercial properties, such as stamina or rust resistance.Complying with melting and alloying, the Aluminum is put right into mold and mildews to produce desired shapes. Cooling and solidification occur, during which the material handles the form of the mold. After solidification, spreadings are removed and may call for further processing, consisting of trimming, machining, or surface area treatment to achieve the final specifications. Quality assurance is essential throughout the procedure, ensuring that the created components fulfill market requirements. On the whole, Aluminum Foundry processes are crucial for generating a large range of lightweight and durable items used in numerous applications.

Sand Casting Methods

A considerable section of Aluminum castings are created utilizing sand spreading methods, which is a flexible technique favored for its capability to create intricate forms. In this procedure, a mold is made from sand mixed with a binding representative, ensuring it can stand up to the liquified Aluminum's temperature level. The pattern, normally made from steel or plastic, is placed in the sand to form the tooth cavity for the spreading. After removing the pattern, the mold and mildew is filled up with molten Aluminum, which strengthens right into the preferred shape upon cooling.Sand spreading is especially advantageous for low to medium production volumes because of its cost-effectiveness and flexibility. In addition, it enables very easy adjustments of mold layouts, suiting different part geometries. It might not accomplish the dimensional accuracy of various other casting methods, the surface finish can be enhanced through succeeding machining. Generally, sand spreading stays a keystone of Aluminum Foundry procedures, making sure varied applications across sectors.

Pass Away Spreading Approaches

In the domain of die casting methods, two main processes attract attention: the warm chamber and cold chamber strategies. Each technique provides one-of-a-kind benefits and difficulties, specifically concerning efficiency and product compatibility. Furthermore, the option of die materials plays a crucial role in figuring out the general success and longevity of the spreading procedure.Warm Chamber Process

Cold Chamber Process

Cold chamber die casting represents an alternative approach for creating Aluminum components, specifically when taking care of metals that have greater melting points or when the molten steel is too reactive for hot chamber processes. In this technique, molten Aluminum is poured right into the die from an outside ladle, which minimizes the danger of contamination and permits higher adaptability in alloy choice. The process involves injecting the molten steel into a cold die making use of a hydraulic piston, making sure specific control over the injection rate and stress. This method is advantageous for producing intricate geometries and attaining high dimensional accuracy. It might need longer cycle times contrasted to hot chamber processes, cold chamber die casting is essential for particular applications in Aluminum shops.Die Materials Option

Choosing the ideal die materials is crucial for maximizing the die casting procedure and guaranteeing the long life and performance of the mold and mildews. The most typically utilized products include device beryllium-copper, steel, and Aluminum alloys, each offering distinct advantages. Tool steel is favored for its resilience and resistance to wear, making it perfect for high-volume production runs. Aluminum gives outstanding thermal conductivity, promoting reliable heat dissipation, while beryllium-copper alloys incorporate strength and thermal monitoring buildings, however at a higher price. Factors affecting the selection consist of the complexity of the part, anticipated manufacturing volume, and the specific Aluminum alloys being cast. Eventually, the right option of die material can considerably boost efficiency and minimize overall operational expenses in Aluminum shops.Investment Casting Processes

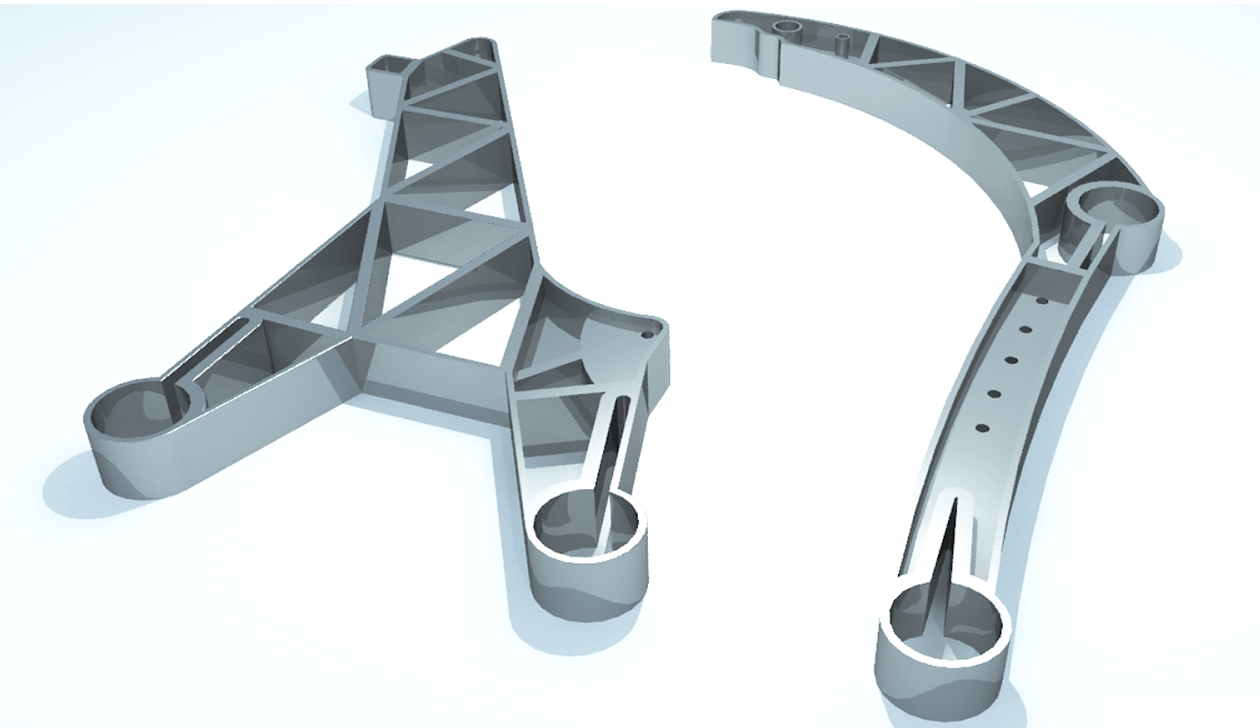

While numerous casting approaches exist, investment spreading attracts attention for its capability to generate detailed shapes with high accuracy and outstanding surface area coatings. This procedure entails developing a wax pattern that is covered with a ceramic shell. When the shell hardens, the wax is melted away, leaving a dental caries that is filled with liquified Aluminum.Investment spreading is especially useful for producing complex geometries that would certainly be difficult or impossible to accomplish with various other techniques. It allows for limited resistances, lowering the need for substantial machining post-casting. In addition, the smooth surface finish lessens the requirement for second operations, consequently improving effectiveness.

This method is widely utilized in sectors requiring comprehensive components, such as aerospace and clinical sectors. The adaptability of investment casting allows the manufacturing of both small and big amounts, making it a valuable option in Aluminum foundries seeking to satisfy varied production needs.

Long-term Mold And Mildew Casting

Long-term mold and mildew spreading is a technique that uses recyclable molds to produce Aluminum elements, boosting performance in production. This strategy offers several benefits, consisting of boosted dimensional accuracy and surface finish, making it ideal for different industrial applications. By recognizing its procedure, benefits, and makes use of, one can value its relevance in the Aluminum Foundry industry.Refine Introduction

Aluminum Foundry procedures incorporate different methods, among which is irreversible mold and mildew casting. This technique utilizes recyclable mold and mildews, normally made from steel, permitting effective manufacturing of Aluminum parts. The procedure starts with pre-heating the mold to enhance fluidness and decrease problems. Molten Aluminum is after that poured right into the mold and mildew under gravity or stress, making certain accurate filling and reducing air entrapment. When the Aluminum strengthens and cools Aluminum Foundry down, the mold is opened up to fetch the cast part. Irreversible mold and mildew spreading is recognized for producing premium, dimensionally accurate components appropriate for numerous applications. The method is especially helpful for high-volume manufacturing runs, as it greatly lowers material waste and boosts repeatability in manufacturing procedures.Advantages of Strategy

Although numerous casting approaches exist, permanent mold and mildew spreading offers unique benefits that make it a preferred selection for lots of suppliers. This strategy allows for premium dimensional accuracy and surface finish, minimizing the need for considerable machining. The recyclable mold and mildews, normally made from steel, enhance manufacturing efficiency by permitting quick cycle times and reduced general product costs. On top of that, irreversible mold and mildew casting advertises boosted mechanical buildings in the last item because of the regulated air conditioning prices, which result in finer grain structures. Furthermore, as the procedure generates less waste contrasted to sand casting, it is much more eco-friendly. On the whole, these benefits add to cost-effectiveness and high-quality results, making irreversible mold and mildew casting a strategic choice in the Aluminum Foundry sector.

Applications in Market

In various industries, long-term mold and mildew spreading plays an essential duty in generating top quality Aluminum components, particularly where accuracy and longevity are paramount - Aluminum Foundry. This method is widely made use of in the vehicle sector for producing engine blocks, transmission housings, and various other crucial parts that call for precise tolerances and robust performance. The aerospace field benefits from long-term mold and mildew casting for components that have to stand up to severe conditions while keeping light-weight qualities. In addition, customer items often use this strategy for creating resilient and cosmetically pleasing items, such as kitchenware and attractive fixtures. The ability to attain intricate geometries and fine surface coatings makes permanent mold and mildew casting a preferred selection across varied applications, ensuring effective and trusted manufacturing in various commercial contextsMachining and Finishing Workflow

Accuracy machining and completing operations play a necessary role in the Aluminum Foundry procedure, making sure that cast components fulfill stringent high quality and dimensional requirements. These procedures entail various methods, such as milling, transforming, exploration, and grinding, which are used to fine-tune the surfaces of cast parts. Each method is chosen based upon the details demands of the part, including its dimension, form, and designated application.Ending up procedures, such as anodizing and surface area polishing, improve the aesthetic charm and rust resistance of Aluminum components. Furthermore, these procedures help attain tighter tolerances and smoother surfaces, which are important for performance in different commercial applications.

Quality Assurance in Aluminum Foundries

Quality control in Aluminum factories is an essential element that ensures the stability and performance of cast items. This process includes organized examinations and screening at numerous phases of production. Foundries carry out extensive high quality checks, consisting of aesthetic examinations, dimensional dimensions, and product analysis, to establish that every cast meets defined standards.Furthermore, progressed strategies such as non-destructive testing (NDT) are used to discover interior problems that might not be noticeable on the surface. By checking variables like temperature level and alloy composition, foundries can preserve excellent manufacturing conditions, minimizing the probability of problems.

Adherence to sector requirements, such as ISO qualifications, reinforces a shop's commitment to high quality. Continual training and advancement of personnel also play an essential duty in promoting a society of quality understanding. Inevitably, efficient top quality control techniques boost consumer complete satisfaction and lessen costly rework and scrap, ensuring the Foundry's affordable side out there.

Regularly Asked Concerns

What Precaution Are Needed in An Aluminum Foundry?

Precaution in An Aluminum Foundry include proper personal safety equipment, ventilation systems to manage fumes, fire avoidance protocols, regular equipment upkeep, worker training on dangers, and emergency feedback intends to resolve potential accidents effectively.How Does Recycling Aluminum Affect Foundry Processes?

Recycling Aluminum considerably affects Foundry procedures by decreasing resources expenses, minimizing waste, and decreasing power usage. This environment-friendly technique boosts manufacturing efficiency while promoting sustainability, eventually profiting both the Aluminum and the atmosphere industry.What Are the Ecological Influences of Aluminum Foundries?

The ecological effects of Aluminum factories consist of air and water pollution, high power usage, and significant greenhouse gas exhausts. These aspects contribute to habitat damage and health risks for bordering areas, demanding enhanced sustainability techniques.How Do Foundries Manage Waste and Emissions?

Foundries handle waste and emissions through numerous strategies, including reusing scrap metal, executing purification systems, and adhering to ecological policies. These procedures aim to decrease ecological effect while keeping operational performance and performance.What Is the Duty of Automation in Aluminum Foundries?

Automation in Aluminum shops enhances performance and accuracy. It reduces human mistake, optimizes manufacturing procedures, and lowers labor costs. By incorporating sophisticated modern technology, factories can enhance product quality and warranty consistent operational efficiency.Aluminum Foundry processes include a collection of specialized techniques intended at changing raw Aluminum right into usable parts. These procedures usually begin with thawing the Aluminum, where main or scrap Aluminum is heated up until it reaches a molten state. The warm chamber process is a very reliable die spreading approach frequently made use of for Aluminum alloys. Cold chamber die spreading represents a different approach for creating Aluminum elements, specifically when dealing with steels that have higher melting factors or when the molten steel is also responsive for hot chamber procedures. Aluminum Foundry. Aluminum Foundry processes include various strategies, one of which is permanent mold and mildew casting

Report this wiki page